Drying Processing

Optimizing Product Quality Through Fluidized Bed Drying

Fluidized Bed Drying (FBD) is a vital step in the manufacturing of many powders, granules, and crystals. As opposed to traditional methods, FBD offers faster dry times with uniform drying conditions. If properly implemented, FBD provides an ideal solution for the gentle drying of your products. Brimrose NIR spectrometers are the perfect tools for in-line continuous monitoring of Fluidized Bed Dryers and Lyophilization.

FBDs operate by circulating heated air suspending the product and ensuring that each granule is being dried. This process is regulated by the heat of the air, the force of the updraft from the fan, and the time spent in the dryer.

REQUEST INFORMATION

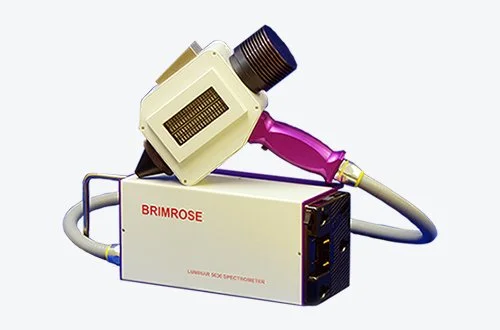

Brimrose Luminar 5030 AOTF-NIR Spectrometer Mounted on FBD

A BETTER METHOD

AOTF-NIR spectroscopy is a non-destructive and rapid test method for determining moisture in a FBD.

Monitor drying for Every Batch: The flexible design allows you to move the unit from FBD to FBD.

Control Your Drying: Continuous monitoring provides accurate control of your drying process.

Brimrose Luminar 5030 AOTF-NIR Spectrometer for FBD Processing

A PROVEN BENEFIT

Successful implementation of a Brimrose AOTF-NIR spectrometer results in:

Increased Control Over Drying

Shortened Dry Time

Real-Time, In-line Monitoring

Extremely Fast Measurement Speed

SOLUTION NOTES

We deliver NIR Application Reports related to drying‑process monitoring, highlighting how our NIR solutions help optimize drying performance and improve product quality. Some proven application reports in drying‑process monitoring are listed below.

On‑Line Measurement of Moisture in a Glatt™ Fluidized Bed (a real‑time drying process monitoring application )

Real‑Time On‑Line Analysis of Lyophilized Pharmaceuticals (freeze‑drying (lyophilization))

Determination of Percent Solids and Drying Rate in Lost‑Foam Coatings (an at‑line drying study)