Luminar 4090 Blending AOTF-NIR Spectrometer

Real‑Time, In‑Line Blend Monitoring for Every Batch

We’re proud to introduce the new Luminar 4090 Blending AOTF‑NIR Spectrometer—a non‑destructive, rapid testing device for assessing blending uniformity. It is designed for easy mounting on blenders and allows customers to conveniently move the unit from one blender to another.

Proper blending is vital to assure batch uniformity and the integrity of drug products. It is important that the Active Pharmaceutical Ingredient (API), excipients, and lubricants in each batch are uniform and homogeneous. A batch that is not fully blended can affect bio-availability in the end product and potentially harm the consumer.

PRODUCT INFORMATION INQUIRY

TECHNICAL SPECIFICATION

| Spectral Range Options | 1100-2300 nm |

| Measurement Modes | Diffuse Reflectance |

| Spectral Resolution | 2-10 nm |

| Wavelength Accuracy | ± 0.5 nm |

| Wavelength Repeatability | ± 0.01 nm over more than 5 years’ service |

| Wavelength Increment | Software Selectable 1-10 nm |

| Ambient Light Rejection | > 106 |

| S/N at 70% Range | < 30μabs, for <5 seconds integration time |

| Photometric Range | 3.5 AU |

| Linearity | Better than 0.15% |

| Sampling Speed | 16,000 wavelength/sec |

| Sampling Area | 3-10 mm (custom) |

| Sampling Distance | 20-100 mm (custom) |

| Internal Diagnostic | 10 Built-in monitoring sensors |

| Power Consumption | 3.5A at 12VDC |

| Battery | 14.8V Lithium-Ion Battery (4.7 hours with 135Wh, 9.4Ah capacity) |

| Communication | TCP/IP and Wireless |

| Software Package | Windows-based analytical software for data acquisition |

| Enclosure | Environmentally Sealed NEMA with Optional IP Rating |

| Communication | Wireless, OPC UA, Modbus (Serial or TCP), I/O with 4-20mA, TCP/IP Ethernet |

| Unit Weight | ~8.7lbs Without Battery |

| Unit Dimensions (W x L x D) | 200 mm x 150 mm x 81 mm |

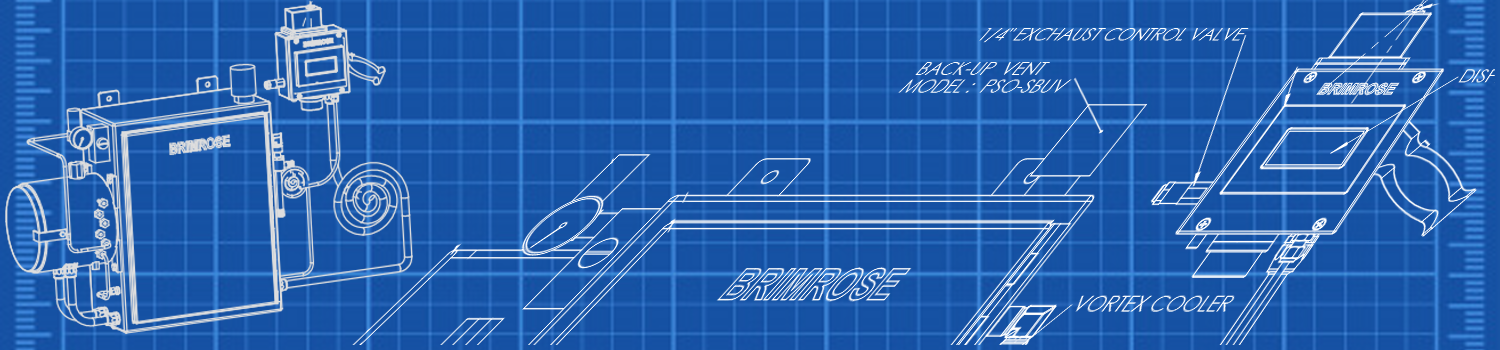

Brimrose Luminar 4090 Mounted on a V-shape Blender

REAL-TIME MONITORING FOR EVERY BLEND

The Luminar 4090 is a compact, high‑performance NIR analyzer designed to optimize blending and ensure uniform product quality, preventing both over‑ and under‑blending while giving manufacturers complete control of the process.

The Blend Results That Matter

- Ensured Quantitative & Qualitative Blend Accuracy

- Faster Product Turnover

- Reduced Blend Time

- Less Waste Product

- Assured Uniformity Across Every Batch